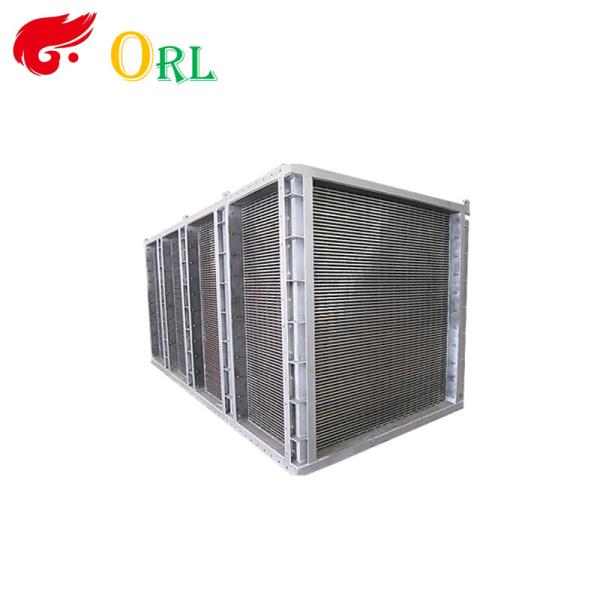

High Temperature Solid Fuel Boiler Enamel Air Preheater In Cement

Plant

Descriptions:

Air preheater(APH)is the shell and tube type heat exchangers used

for preheating the air which is fed to the boiler or furnaces/

kilns for combustion of fuels. Air preheater’s primary objective is

to extract the waste heat from the flue gases leaving the boiler.

There are two types of air preheaters for use in steam generators

in thermal power stations: One is a tubular type built into the

boiler flue gas ducting, and the other is a regenerative air

preheater.These may be arranged so the gas flows horizontally or

vertically across the axis of rotation.

Advantage of air preheater

- Increases thermal efficiency of the system

- Payback period is very short and increase combustion rate

- Improve and strengthen the combustion

- Reduces the loss of furnace and the exhaust gas temperature,

improve the boiler thermal efficiency.

- Air preheater is suitable for all standard fuels

- They are easy for retrofit into existing systems

- These air preheaters are suitable for all waste heat boiler / flue

gas boiler / boiler types.

- They strengthen the heat transfer

| Material | Carbon steel or equivalent |

| Structure | vertical |

| Tubes | enameled seam or seamless tubes |

| Tube OD | Customized |

| Enamel thickness | 0.34+/-0.06mm |

| Size | Customzied design |

| Brand | ORL |

| Remarks | Customized order is also accepted. |

| Manufacturing process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment(Normalizing+

tempering) → Inspection→Cutting→Pipe piercing→welding→Sealing

test→Painting→Packaging |

Enamel air preheater products are classified as following by

application

1. Air preheater designed for denitration renovation projects

2. Enamel air preheater for circulating fluidized bed boiler and

pulverized coal boiler

3. Enamel air preheater for garbage incinerators and biomass

boilers

4. Enamel air preheater for grate furnaces, like chain grate

furnaces

5. Enamel air preheater for gas-fueled boilers, such as kerosene

boilers, coke ovens, etc.

| Name&Type | Supply Ability: | FOB Price |

| Boiler drum | 100Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler header | 100Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler waterwall panel | 500Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler economizer | 500Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler super heater | 300Ton/Tons per Month | Contact Me Get Latest Price |

| Boiler air preheater | 300Ton/Tons per Month | Contact Me Get Latest Price |

| Other | 300Ton/Tons per Month | Contact Me Get Latest Price |

Boiler Parts

Boiler Drum,Boiler Waterwall Panel,Boiler Economizer,Boiler

Header,Boiler Cyclone Separator,Boiler Chimney Flue Pipe,Boiler Air

Preheater,Boiler Air Preheater

Boiler Parts

Boiler Super Heater,Boiler High Temp Superheater,Boiler Cyclone

Separator,Boiler Flue,Boiler Heat Pipe Air Preheater,Boiler Gen

Bank,Boiler Heat Pipe Elements,Boiler Tube Pin,Boiler

Tubeshield,Boiler Ditch Tube

Company Information

Suzhou ORL Power Engineering Co., Ltd.is located in Suzhou, Jiangsu

Province.

ORL Power is a leading company and exporter of industrial

boilers,power plant boilersand boiler parts (including steam drum,

membrane waterwall panel,header,economizer, evaporator,

superheater,H-fin economizer, spiral fin tube, air preheater, heat

pipe, flue etc.), seamless steel tubes/pipes and ERW steel

pipes.ORL provides our customer with full range of services

including boiler design, fabrication, installation and

commissioning, boiler maintenance, and supervision at site. Our

product and service include design and manufacture industrial

boilers, pressure vessels and tanks, and pressure parts for power

plant boilers (600MW, or 1000MW).

Product Description

Boiler Parts

Boiler Drum,Boiler Waterwall Panel,Boiler Economizer,Boiler

Header,Boiler Cyclone Separator,Boiler Chimney Flue Pipe,Boiler Air

Preheater,Boiler Air Preheater

Boiler Parts

Boiler Super Heater,Boiler High Temp Superheater,Boiler Cyclone

Separator,Boiler Flue,Boiler Heat Pipe Air Preheater,Boiler Gen

Bank,Boiler Heat Pipe Elements,Boiler Tube Pin,Boiler

Tubeshield,Boiler Ditch Tube

Production Workshop

Boiler Product Test

Impact test,The scene to examine the water-wall,Industrial TV

monitoring,Snake-like pipe water pressure test,Header endoscopic

detection,Header weld inspection

Testing Center

Packaging & Shipping

Certifications

We have our boiler manufacturing plant, and obtain ISO9001:2008,

ISO3834, ASME S, U and GB stamp.

Company Business

Our products have been wildly used in power plants and large

international companies overseas.

Such as USA, Brazil, Porto Rico, Guatemala, Spain, Demark, Norway,

Turkey, India, Korea, Australia, Middle East, Southeast Asia etc.

Trading Process

ORL offers prompt response, professional products, and all-around

service to our customers. Our experienced sales team and engineers

are waiting for your enquiry and ready to provide sincere service.

We cordially welcome domestic and overseas friends to visit our

company and manufacturing bases, and look forward to building up

long-term, mutual cooperative relationship with you.

FAQ

1. Why choose us?

We are boiler and boiler parts(boiler drum, boiler waterwall panel,

boiler economizer, boiler header, boiler cyclone separator, boiler

flue pipe, boiler air preheater, boiler pipe, boiler

tube)manufacture and we are one of the best suppliers in China.

We ensure the deliver time, high quality, and the best after-sale

service for you.

2. How to order?

Welcome come to our factory for inspecting and discussion the

technical details.

Contact Information

ADD: 11 East Renmin Road, Zhangjiagang City, Jiangsu, China

Phone:+86 0512-56770166

E-mail: info@orlpower.com

Website: www.boiler-units.com